100lpm 300bar 4500psi 2.2kw High Pressure Diving Gasoline Type Air Compressor for Scuba

Basic Info

| Compress Level | 3-Stage |

| Refrigerant Type | Air |

| Name | Mch-6 300bar Scuba Diving Air Compressor |

| Model | Mch6 |

| Flow Rate | 80~100L/Min |

| Working Pressure | 300bar |

| Power Supply | 380V/50Hz/3 Phase(or Cutomized) |

| Cooling Method | Air Cooling |

| Certification | CE |

| Weight | 39kg |

| Transport Package | Standard Export Package for Air Compressor |

| Specification | 125× 70× 92cm(L*W*H) |

| Origin | China |

| Production Capacity | 5000 Sets / Year |

Product Description

MCH-6 300bar Italian Type Scuba Diving Air Compressor For Breathing Air For Sale

100LPM 300bar 4500psi 2.2kw High Pressure Diving Gasoline type Air Compressor For ScubaMain parameters

- Model:MCH6/EM/ET/SH

- Work pressure:30Mpa (300bar)

- Air Displacement (inhalation state):80~100L/min L/min

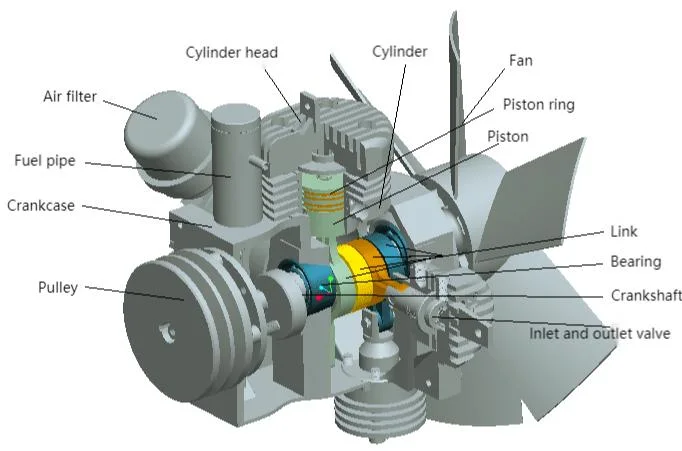

- Type:X-type layout-four-cylinder four-stage reciprocating piston compression

- Drive:Electric 220V/50Hz/2.2kw or 380V/50Hz/3kw or Honda gasoline engine drive

- Lubrication method:Splash lubrication

- Cooling method:Air-cooled

- Control method:Manual shutdown or (optional to automatically shut down to pressure)

- Clean air:1 air filtration, 1 oil-water separation, 1 air purification

- Safety devices:Final stage installation valve, transmission part installation protective cover

- Packing size (length×width×height): 35×65×39cm

- Weight:39kg

- Inflation speed:It takes about 22 minutes to fill a 6-liter bottle with 30Mpa

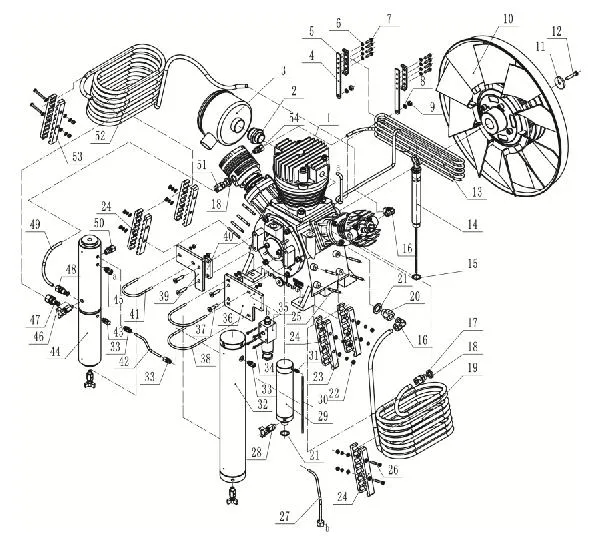

The rotating part is equipped with a protective cover device to ensure the safety of the operator; High-strength nylon cooling fan for better heat dissipatione; Three-cylinder three-stage compression, low compression ratio, reliable performance; Motor drive or gasoline engine drive to meet the gas supply demand under various conditions; Splash-type high-efficiency lubrication; Air filter (paper filter element); Oil-water separator (standard with manual blowdown); Air purification system (standard with manual blowdown) activated carbon, molecular sieve, carbon monoxide absorption molecules constitute a triple breathing air purification system, reusable packing cartridge, simple and convenient replacement, saving cost; Manual shutdown function (optional automatic shutdown); Final safety valve, automatic discharge of over pressure; Shockproof pressure gauge 0~5800psi/400bar; The compressor base is made finely and durable; Stainless steel cooling system;

1,Product name

2,Product Picture

3,Main parameters

- Model:HY-W400

- Work pressure:30Mpa Mpa(300bar)

- Displacement (inhalation state):400L/min L/min

- Type:W-type layout-three-cylinder three-stage reciprocating piston compression

- Drive:Electric 380V/50Hz/7.5kw or honda gasoline engine drive

- Lubrication method:Splash lubrication (food grade lubricant 750-H2)

- Cooling method: air cooling

- Control method:Automatic shutdown

- Clean air:Primary air filtration, secondary oil-water separation, secondary classification air purification

- Safety devices:Interval safety valve, pressure maintenance valve, automatic shutdown system, transmission part installation protective cover

- Packing size (length×width×height):125×70×92cm

- Weight:210kg

- Inflation speed:It takes about 7 minutes to fill a 6-liter bottle with 30Mpa

- Certified product:CE certification

- Packing List:Manual,safety inspection report certificate, 2 sets of inflation hoses and joints, and the machine has built-in food-grade lubrication.

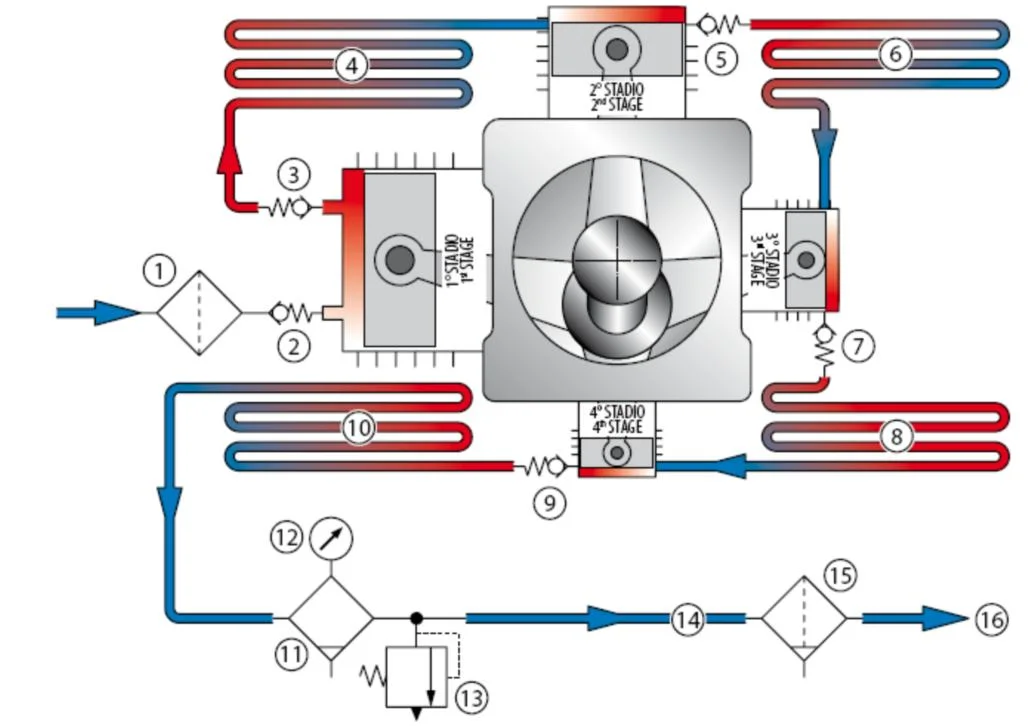

4,Working principle

This product is mass-produced after design changes and optimizations in accordance with the Italian model. The final piston adopts a special process, and the piston ring adopts the Japanese Riken process. Unanimous praise from users. This product adopts three-cylinder three-stage compression, splash lubrication, inter-stage safety valve and filter system. HC-W300 can provide safe compressed air for any industry that needs high-pressure pure air source, and provide safe compressed air that meets the requirements of human breathing. This product is designed, produced and tested and accepted in accordance with the requirements of GB/T 12929-2008 "Marine High Pressure Piston Air Compressor"; the air quality meets the EN12021 international breathing compressor breathing standard; HC-W300 is a kind of air compression equipment, it will be free 1 kg (1bar/0.1Mpa) of the air in the state is compressed to a high pressure gas with a gauge pressure of 300 kg (300bar/30Mpa). The oil and impurities in the high-pressure air can filter the inhaled air containing fine particles (PM2.5) to a safety value of less than 10 micrograms, which meets the standards set by the World Health Organization, making the exhaust gas clean and tasteless. The personnel provide highly purified, clean, odorless, safe and reliable compressed breathing air.5,Product composition and characteristics

Standardized assembly-mass production

The machine is equipped with an automatic shutdown device, the shutdown pressure can be set freely, and it is equipped with a time running timer to support the maintenance time;

Two gas cylinders can be filled at the same time; (1 bottle is recommended for filling faster)

High-power all-copper core wire customized motor, stable power output, light starting load;

The protective cover adopts plastic spraying process, which is not easy to scratch and rust; (some manufacturers use spray paint, which is low in cost and easy to fall off and rust)

Super V-belt, strong tension, wear-resistant and high-temperature resistant;

Shockproof pressure gauge 0~5800psi/400bar, accurate pressure value;

The reinforced steel plate base is equipped with anti-vibration pads, so the equipment runs more smoothly;

High-strength nylon cooling fan, better heat dissipation effect;

The low pressure adopts red copper tube, which has better heat dissipation performance, and the high pressure adopts stainless steel tube to ensure the safety of output pressure;

The rotating parts are equipped with protective cover devices, and all levels are equipped with safety valves and automatic shutdown systems to ensure the safety of operators;Optional motor drive or gasoline engine drive to meet the gas supply needs under various conditions;Configure precision air filter (customized wire mesh filter element);

2-stage oil-water separator (standard manual blowdown, optional automatic blowdown) final classification air purification system (standard manual blowdown, optional automatic blowdown) two-stage purification, first removes water, then removes odor;(Most manufacturers use level 1 mixed filtration to save production costs)The last stage adopts piston ring technology, and only the piston ring needs to be replaced when worn;(Most manufacturers do not use the final stage piston ring process, and need to replace a complete set of pistons and cylinders after wear, and pay for expensive accessories)The end adopts a pressure maintenance valve, deep air filtration, and extends the life of the filter element, and adopts an alloy aluminum permanent filter element, a replaceable filter element material, and saves later use costs;(Some manufacturers have no pressure maintenance valve and use disposable filter elements, which saves production costs and increases later use costs)The parts in contact with gas, such as cylinders and filter cartridges, are cleaned with alcohol before leaving the factory, and tested with food-grade lubricating oil. The factory has been debugged.

6,Main application

Diving cylinder fillingFire gas cylinder filling

Fire breathing application: Equipped in the gas supply stations of the fire brigade or various fire-fighting vehicles, it provides emergency gas supply at the scene of a fire or in the rescue and relief process, so that the majority of firefighters will be exposed to various environments such as dense smoke, poisonous gas, steam or oxygen deficiency. Breathing high-purity, clean, odorless, safe and reliable compressed air ensures that fire extinguishers can safely and effectively carry out fire fighting, rescue, disaster relief, and rescue.

Diving breathing application: Diving clubs, diving enthusiasts, marine breeding, marine rescue, shipboard equipment, underground operations, fishery fishing, aquaculture, sunken object salvage, underwater engineering, water parks, shipbuilding and other industries, providing divers with high purification, clean and tasteless , Safe and reliable compressed breathing air. In an environment that cannot meet the requirements of the human body for normal breathing, the air is filled into a high-pressure gas cylinder for human breathing.

- Product display

Customized for the air compressor is accepted .

Q1: If you accept small orders?A1: Yes , feel free to contact usQ2: Can you send products to my country?A2: Sure, we can. If you do not have your own ship forwarder, we can help you.

Q3: Can you do OEM for me?A3: YES, OEM is welcomed .Q4: What's your payment terms ?A4: By T/T,LC AT SIGHT,30% deposit in advance, balance 70% before shipment.Q5: How can I place the order?A5: First sign the PI,pay deposit,then we will arrange the production.After finished production need you pay balance. Finally we will ship the Goods. Q6: When can I get the quotation ?A6: We usually quote you within 24 hours after we get your inquiry. If you are very urgent to get the quotation.Please call us or tell us in your mail, so that we could regard your inquiry priority.